Description

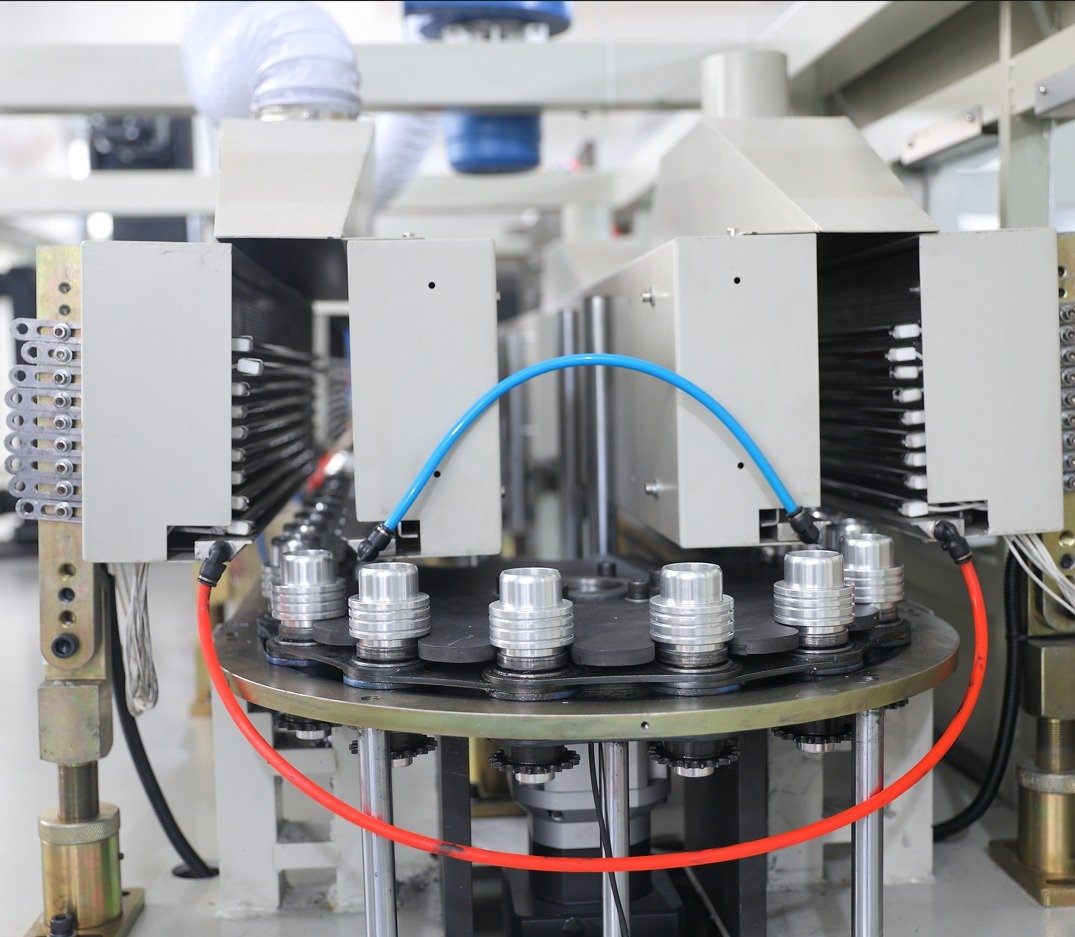

YD 6 cavity Automatic Bottle Blowing Machine

Yuda’s full servo variable pitch high-speed energy-saving one-out six-blowing machine has a stable production capacity of up to 15000BPH (0.2L-0.75L) for a single machine, and is compatible with 1.5L production capacity of 10000BPH; the equipment has set the blowing formula for different containers at the factory, and no manual adjustment is required. The corresponding formula can be switched at will according to the user’s different containers. The remote control system can be optionally equipped to better guarantee the after-sales timeliness. The PTO (servo-set modular system is adopted, which is efficient, energy-saving and stable. It is suitable for blowing light-weight containers.

- Reasonable design and fully automatic control greatly reduce power consumption and manpower.

- Infrared preheating heating box is used to preheat the tube blank.

- The production process is fully automated, with the advantages of low investment, quick results, convenient and safe operation and maintenance.

Parameters of Automatic Bottle Blowing Molding Machine

| Model | | | FG4 | FGX4 | FG6 | FGX6 | FG8 | FGX8 |

| | Mold number(piece) | 4 | 4 | 6 | 6 | 8 | 8 |

| | Max capacity(BPH) | 7200 | 8500 | 9600 | 12000~130000 | 12000 | 15000-16000 |

| Bottle specification | | Max volume(ml) | 2000 | 2000 | 2000 | 2000 | 2000 | 750 |

| | Max height(mm) | 328 | 328 | 328 | 328 | 328 | 300 |

| | Round bottle max diameter(mm) | 105 | 105 | 105 | 105 | 105 | 75 |

| Preform specification | | Suitable inner bottle neck(mm) | 20-25 | 20-25 | 20-25 | 20-25 | 20-25 | 20-25 |

| | Max preform length(mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| Electricity | | Total installation power(kW) | 51 | 51 | 74 | 97 | 97 | 97 |

| | Heating oven total power(kW) | 46 | 46 | 69 | 92 | 92 | 92 |

| | Heating oven real power(kW) | 26 | 26 | 40 | 42 | 50 | 48 |

| | Voltage/frequency(V/Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) |

| | Allowed voltage fluctuation range | ±10% | ±10% | ±10% | ±5% | ±10% | ±10% |

| Compressed air | | Pressure(bar) | 30 | 30 | 30 | 30 | 30 | 30 |

| | Air consumption(㎥/min) | 4 | 6 | 5.5 | 8~10 | 7 | 10 |

| Cooling water | Mold water | Pressure(bar) | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 |

| | Temperature regulation range(℃) | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 |

| | Flow rate(L/min) | 45 | 45 | 45 | 45 | 45 | 45 |

| Oven water | Pressure(bar) | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 |

| | Temperature regulation range(℃) | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 |

| | Flow rate(L/min) | 22 | 22 | 22 | 45 | 22 | 45 |

| Machine specification | Machine dimension(m)(L*W*H) | | 3.3*1*2.3 | 4.6*1.3*2.3 | 4.3*1*2.3 | 5.5*1.3*2.5 | 5.5*1.3*2.5 | 5.5*1.3*2.5 |

| Machine weight(Kg) | | 3500 | 4500 | 4500 | 6500 | 6500 | 6500 |

Reviews

There are no reviews yet.