Description

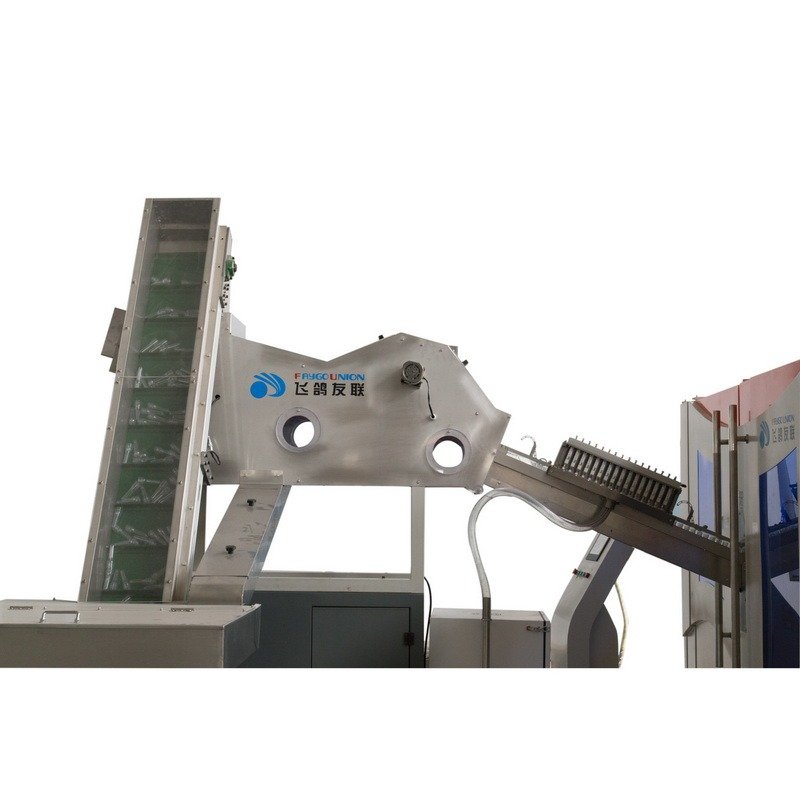

Three-in-one blowing filling capping machines are popular in the beverage industry, particularly for the production of carbonated drinks. As they offer a streamlined and efficient process for producing and packaging large quantities of products. The integration of the three functions results in a continuous and automated production process, reducing the need for manual intervention and increasing productivity. The machine can be configured with different numbers of bottle filling nozzles to suit different production requirements, and different bottle sizes, shapes, and capacities can also be accommodated. The machine can be controlled by a programmable control system that monitors and controls the entire process. Enabling the operator to adjust and fine-tune different settings to optimize production efficiency and output.This model of filling machine is designed for the low/middle capacity and small factory. It takes low buying cost, low water and electricity consumption and few space occupation into consideration at the beginning.

At the same time it can perfectly complete the function of washing, filling and capping. It improves the sanitary conditions and simplifies the maintenance compared with the last generation water filling machine.

| Model | FG4 | FGX4 | FG6 | FGX6 | FG8 | FGX8 | ||

|---|---|---|---|---|---|---|---|---|

| Mold number(piece) | 4 | 4 | 6 | 6 | 8 | 8 | ||

| Max capacity(BPH) | 7200 | 8500 | 9600 | 12000~130000 | 12000 | 15000-16000 | ||

| Bottle specification | Max volume(ml) | 2000 | 2000 | 2000 | 2000 | 2000 | 750 | |

| Max height(mm) | 328 | 328 | 328 | 328 | 328 | 300 | ||

| Round bottle max diameter(mm) | 105 | 105 | 105 | 105 | 105 | 75 | ||

| Preform specification | Suitable inner bottle neck(mm) | 20-25 | 20-25 | 20-25 | 20-25 | 20-25 | 20-25 | |

| Max preform length(mm) | 150 | 150 | 150 | 150 | 150 | 150 | ||

| Electricity | Total installation power(kW) | 51 | 51 | 74 | 97 | 97 | 97 | |

| Heating oven total power(kW) | 46 | 46 | 69 | 92 | 92 | 92 | ||

| Heating oven real power(kW) | 26 | 26 | 40 | 42 | 50 | 48 | ||

| Voltage/frequency(V/Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | ||

| Allowed voltage fluctuation range | ±10% | ±10% | ±10% | ±5% | ±10% | ±10% | ||

| Compressed air | Pressure(bar) | 30 | 30 | 30 | 30 | 30 | 30 | |

| Air consumption(㎥/min) | 4 | 6 | 5.5 | 8~10 | 7 | 10 | ||

| Cooling water | Mold water | Pressure(bar) | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 |

| Temperature regulation range(℃) | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | ||

| Flow rate(L/min) | 45 | 45 | 45 | 45 | 45 | 45 | ||

| Oven water | Pressure(bar) | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | |

| Temperature regulation range(℃) | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | 6~13 | ||

| Flow rate(L/min) | 22 | 22 | 22 | 45 | 22 | 45 | ||

| Machine specification | Machine dimension(m)(L*W*H) | 3.3*1*2.3 | 4.6*1.3*2.3 | 4.3*1*2.3 | 5.5*1.3*2.5 | 5.5*1.3*2.5 | 5.5*1.3*2.5 | |

| Machine weight(Kg) | 3500 | 4500 | 4500 | 6500 | 6500 | 6500 |

Reviews

There are no reviews yet.